How To Install Osb On Wall Nailed To Concrete Pad

How-to install a wood subfloor over concrete

Protect your basement from a common cold and clammy concrete flooring

You lot need a dry, clean and flat surface before you can install finished flooring in a room congenital on a concrete slab. I of the simplest options is a sleeper-based subfloor. The result is a subfloor that protects finished flooring from common cold and clammy concrete-based floors.

Difficulty level: Intermediate

Duration: Weekend

Subfloor options

Some garage flooring options are designed to be installed straight on a concrete surface. Others crave some type of subfloor to protect them from the effects of cold, damp concrete. Check the flooring manufacturer's installation instructions before you make your choice.

Go to the article: "Is a subfloor necessary in the basement?" Information technology volition assistance yous choose the correct subfloor for your needs. Follow our helpful tips below earlier installing engineered floor panels in your basement:

Before you begin

-

Check your local building code, and pay special attention to rules concerning vapor barriers, bridge ratings (subfloor thickness) and flooring drains.

-

Use a digital wet detector to measure out the moisture content (MC) of the concrete slab.

-

Read the flooring manufacturer'due south guidelines for the production you lot plan to install, and pay particular attention to requirements every bit regards the structure and wet content of the concrete slab.

-

Manufacturers may require sub-floor and flooring materials to be acclimated prior to installation (generally 24-72 hours).

-

Article of clothing center protection and work gloves, and utilize an approved dust mask or respirator when cutting force per unit area-treated wood.

Components of a wood subfloor

Here are the components of a sleeper-and-woods subfloor:

-

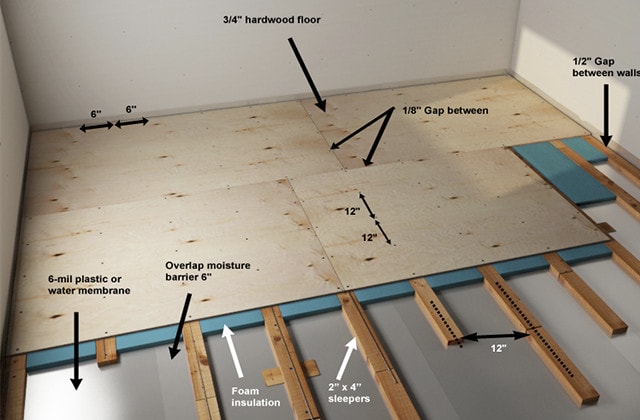

Plastic or water membrane

-

Cream insulation

-

two" x 4" sleepers

-

3/4" hardwood floor

Calculate the surface and decide the layout

1

Calculate the materials required and establish a plan

-

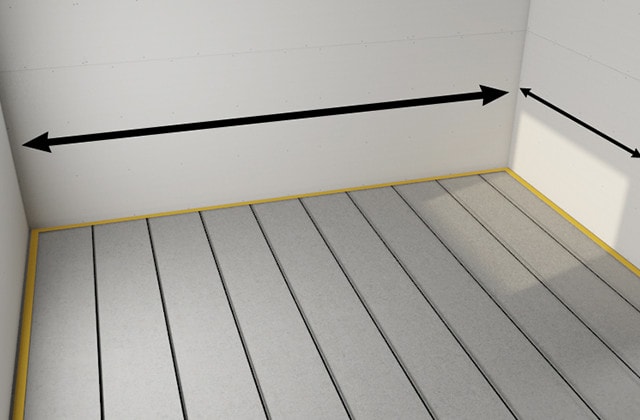

1.1 - Measure the length and width of the room and make a layout programme.

-

1.2 - Calculate the full area of the room (length multiplied past width) which volition indicate the quantities of vapour bulwark, plywood and insulation you will need.

-

1.iii - On your programme, draw the location of sleepers effectually the perimeter of the room and summate the number required (multiples of 8ꞌ and 12ꞌ)

-

1.4 - On the programme, draw parallel sleepers located 12" on centre and calculate the number required.

-

one.5 - Add 10% to full quantities of materials in example of error or lacking pieces

Brand your life easier

Our converters tin can be a big help in calculating the quantity of materials you need.

Cut casings to the level of the new flooring.

-

two.1 - two.1. Remove existing baseboards, moulding and doorway thresholds.

-

2.2 - ii.2. Measure the combined thickness of the subfloor (sleepers and wood panels) and finished floorcovering.

-

2.3 - 2.3. With a saw or oscillating tool, cutting door casings and jambs to 1/16" to a higher place the level of where the finished floor will be.

-

ii.4 - ii.4. If needed, remove doors and use a circular saw to cutting one/8" above the level of where the finished flooring will be. (The bottom of a hollow-core door can only exist cut to a express extent. Never cut the acme of the door.

Identify high and low spots

3

Check for flatness and clean the slab

-

3.i - With a long metal straightedge, identify dips or high spots that exceed recommended tolerances for the floor you are installing (usually within a variance of iii/sixteen" every 10 feet or i/8" every 6 feet).

-

3.2 - Use a concrete grinder to level high spots.

-

iii.3 - Fill depression spots with cocky-levelling compound or Portland cement. Follow the chemical compound manufacturer's recommendations regarding surface training, mixing and drying time.

-

iii.4 - Sweep, vacuum and remove droppings such as drywall compound, paint, dirt, adhesives, tack strips, staples and loose concrete.

-

iii.5 - Fill cracks with concrete filler and smoothen out the surface with the flat edge of a trowel.

-

iii.half-dozen - Let the filler cure, so seal with water-based polyurethane.

Install the polyethylene vapour barrier

4

Install the vapour barrier

-

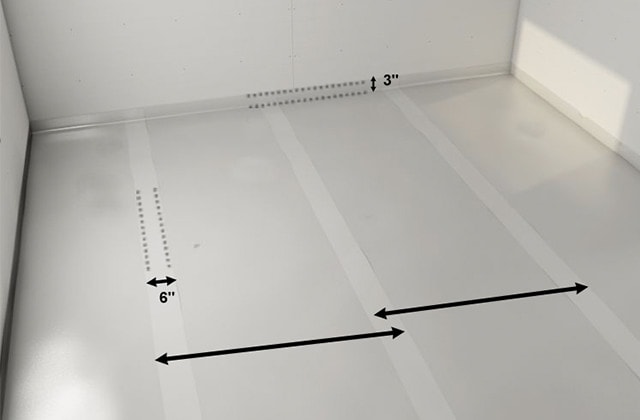

4.one - Comprehend the slab with polyethylene sheeting, overlapping seams by at least 6".

-

iv.2 - Extend approximately iii" of polyethylene upward the walls around the entire perimeter of the room.

-

4.3 - Seal the seams, edges and whatever tears with blueish threescore mm sheating record.

Pro Tip

For additional protection, apply a "skim" glaze of asphalt mastic to the slab with the directly edge of a trowel. After near 30 minutes, the polyethylene sheeting can be rolled over the mastic by walking over the film, embedding it in the mastic.

Infinite 12" sleepers on centre

-

five.ane - Lay flat the pressure-treated ii" x 3"southward around the entire perimeter of the room, maintaining a ½" expansion gap between each two" 10 3" and the walls.

-

5.2 - Use shims to level if necessary, and if several thicknesses are required, glue shims together.

-

5.3 - Screw each sleeper at least two" into the physical slab. Space screws 24" autonomously. Screw heads should lie flush with or only below the surface of the sleepers.

-

5.4 - Lay 2" x three"s in parallel rows 12" apart on-center, perpendicular to the direction of your finished flooring. Butt the joints, leaving a ¼" expansion gap.

-

5.5 - Ensure the sleepers are level, and shim if necessary.

-

five.half-dozen - Fasten the sleepers to the physical at 12" intervals.

Add insulation between the sleepers

6

Position insulation panels

-

vi.ane - Measure the spaces to be filled betwixt the sleepers.

-

six.2 - Marking the cutting lines on the insulation panels

-

vi.three - Use a utility pocketknife and metallic straightedge to score the foam insulation.

-

6.four - Turn over the scored foam panel. Press hard against the back (uncut side) of the scored cutting for a make clean break.

-

vi.5 - Do the same for all panels and place them between the sleepers, on the vapor barrier.

Secure the subfloor to the sleepers

seven

Screw in the plywood subflooring

-

seven.one - Check the plywood panels for chipped tongue-and-groove edges.

-

seven.two - Mensurate and cut the plywood panels so interlocking joints meet at the centre of the sleepers. Stagger the joints then no joint runs into another articulation.

-

7.3 - Before you place each panel, apply a bead of construction agglutinative to the acme of the sleepers.

-

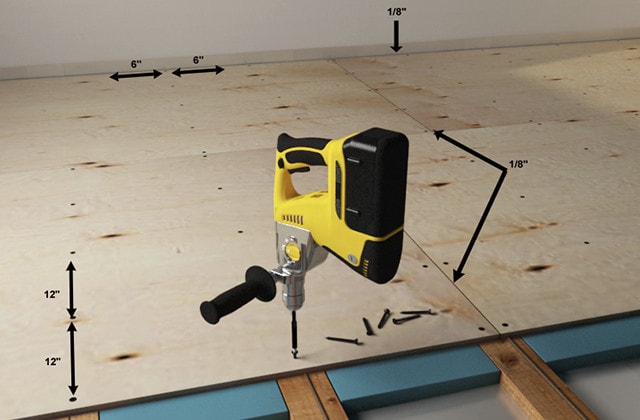

7.4 - Maintain a ane/8" expansion gap around the perimeter.

-

seven.5 - Fasten each plywood console to the sleepers using flooring screws: every 6" around the edges and every 12" along intermediate sleepers.

-

7.six - Clean the plywood subfloor surface before yous install the flooring.

Source: https://www.rona.ca/en/workshop/diy/install-wood-subfloor-concrete-slab

Posted by: rogerssupor1962.blogspot.com

0 Response to "How To Install Osb On Wall Nailed To Concrete Pad"

Post a Comment